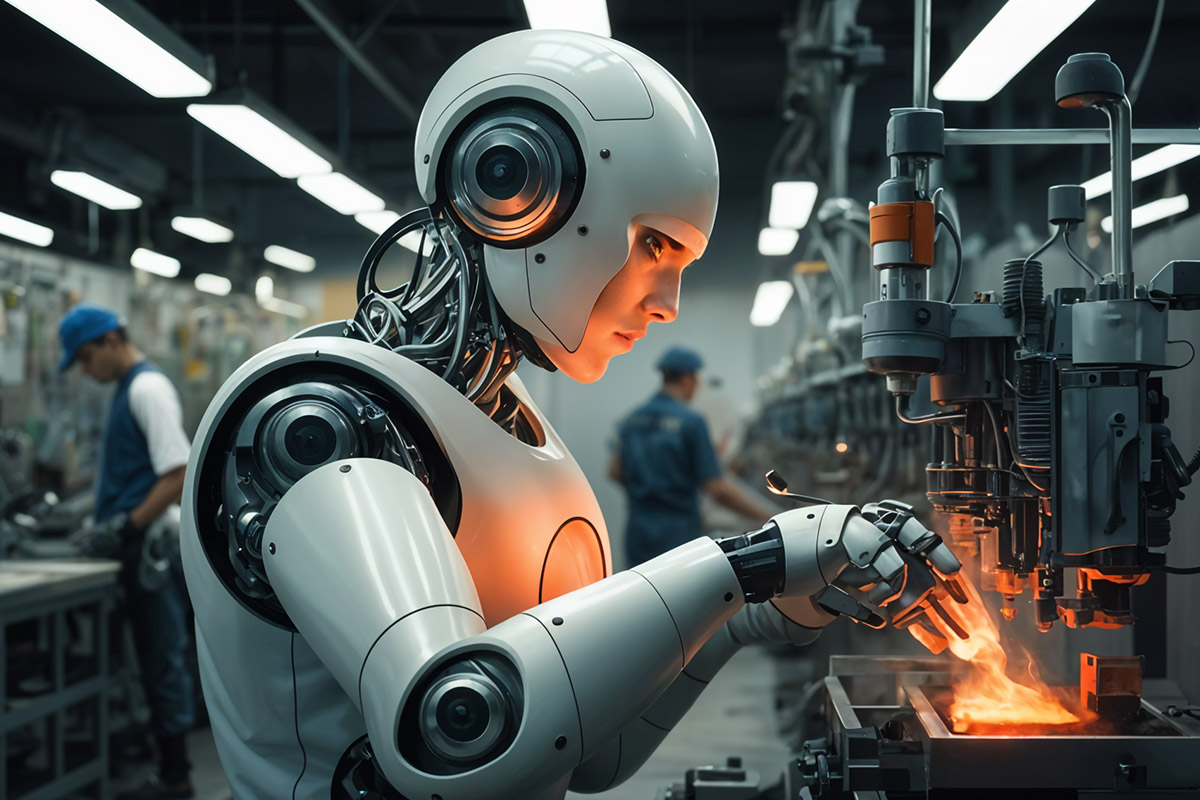

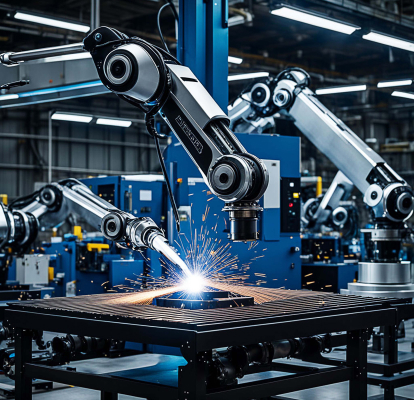

Modern automated machines rely on control panels equipped with advanced and sensitive electrical components — including PLCs, drives, transformers, and thyristors — all of which generate substantial heat during operation.

If this heat isn’t properly managed, it can lead to component failure, performance instability, and unplanned downtime. Additionally, control panels must remain dust-free and moisture-protected to ensure the long-term reliability of these critical systems.

At Yardley Ashton, we design and deliver Compact Panel Air Conditioners that provide effective thermal management for industrial control cabinets. Our systems remove unwanted heat, filter out dust particles, and control humidity — ensuring your equipment operates safely, efficiently, and continuously.

Backed by decades of engineering expertise, Yardley Ashton’s panel air conditioners are built to deliver reliable performance in diverse industrial environments.

Our compact units are easy to install, energy-efficient, and designed to maintain optimal internal cabinet temperatures — regardless of ambient conditions.

Each system is equipped with advanced filtration, corrosion-resistant components, and precise temperature control features that safeguard sensitive electronics from heat, dust, and moisture damage.

To meet modern industry demands, Yardley Ashton has developed a new range of Inverter Panel Air Conditioners.

These systems automatically adjust cooling capacity based on load and ambient conditions — providing up to 50% energy savings while maintaining constant temperature and performance stability.

Key advantages include:

Adaptive cooling for variable load conditions

Reduced power consumption and operating costs

Extended component lifespan due to steady temperature management

Quieter operation and lower maintenance requirements

Compact, durable design suitable for harsh industrial environments

Dust- and humidity-resistant enclosure protection

Energy-efficient compressor and fan technology

Fast installation and easy maintenance access

Available in multiple capacities and mounting configurations

Our Compact Panel Air Conditioners are ideal for:

CNC and automated machinery panels

Electrical cabinets and control stations

Power distribution boards

Communication and instrumentation enclosures

Process automation systems

DATA CENTER COOLING SYSTEMS

For a data center to maintain its efficiency, the cooling requirements must be met. Temperature limits are a critical consideration when designing a data center because they can cause serious server issues. Servers may not operate well when the temperature is too hot or too cold. The environment must be right for optimal performance. Furthermore, if the data center ends up generating too much heat, it could result in extremely high utility bills for the facility. Having proper cooling systems will not only allow you to ensure optimal performance of your servers but also minimize on the energy costs of the facility.

Werner Finley has been supplying high efficiency, superior quality & highly reliable data center cooling solutions for more than a decade. The development of Cooling solutions for data centers have taken a lot of twists over the years, considering various factors that affect their performance. Werner Finley proudly declares that our engineering team has been designing & developing innovative solutions in order to adapt to the changing requirements of modern data centers.

We provide cooling solutions for manufacturing, data centers, pharmaceuticals, food & beverage, and heavy industries.

Each system undergoes strict testing, performance validation, and quality checks to ensure durability and consistency under real-world conditions.

Yes — our engineers design retrofit-friendly cooling systems that integrate seamlessly with your current setup, enhancing efficiency without major overhauls.

Join us to experience cutting-edge industrial solutions that drive innovation, lasting success.

Copyright © 2025 All Rights Reserved.